Use the links below to jump to the related section of information.

Burn-Off Oven Technical Information

Top-Down Heating for Burn-Off Ovens

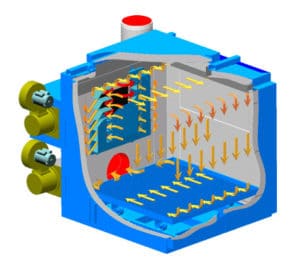

This patented technology (U.S. Patent 5,351,632) has literally turned burn-off oven design upside down by introducing the heat into the top of the oven and removing cooler gases and combustible vapor from the bottom. The advantages of Top Down Heating are more uniform temperatures, control of hottest spot in the oven to prevent part damage and increased efficiency. It makes the process easier to control, lowers particulate emissions, allows ash pans in the bottom of carts, and cart wheels last much longer.

Rate-of-Change Control

This patented system allows Steelman heat-cleaning ovens to process large amounts of material quickly without a fire hazard. It actually measures vapor production inside the oven and controls it at a safe level.

Burn-Off Oven High-Fire Afterburners

The Steelman afterburner gets to temperature quickly and maintains 1,500°F to 1,800°F for more than 1/2 second to meet current and future air quality standards. All Steelman ovens have an afterburner temperature indicator.

Burn-Off Oven Automatic Process Control

This patented, advanced control package (U.S. Patent 5,189,963) is designed to make oven operation totally automatic without operator input. This eliminates the chance of operator error. This package includes Automatic Cycle Timer, Three Level Safety System and a Cool-Down Circuit.

- Automatic Cycle Time – This system can tell when the process is over so the oven runs no longer than necessary to do the job, and won’t shut off prematurely. It automatically adjusts to the load.

- Three Level Safety System – Primary water sprays control the process. If they fail, 20 seconds later the backup nozzle is activated. If it fails, 20 seconds later the primary burner is shut down.

- Cool-Down Circuit – If the afterburner fails for any reason, the water sprays are activated to cool the load to prevent smoke from going up the stack. Automatically shuts off when oven is cooled.

Burn-Off Oven Features

Automatic Process Control (APC)

APC is the ultimate in control systems for a burn-off oven. The purpose of the control system is to provide the quickest cleaning cycle time while protecing the product, operator and the workplace. The APC system automatically adjusts the required cycle time to the weight of the load and the amount of combustible material on the parts; thus, APC provides the shortest possible cycle time for the load being processed. There is no under or over processing with the APC. The control system requires zero input from the operator. Digital temperature controllers are programmed to respond to the rate of temperature change in both the oven and the afterburner; rapid temperature changes are caused by exotherms and excessive combustible vapor levels.

The controllers activate primary water sprays to control the process at a safe rate. Large backup sprays are activated within seconds if the primary sprays are not adequate. In the event that primary and backup water sprays are not able to control a rapid temperature rise, the oven burner will shut down, the afterburner will stay on, and the water sprays will continue to operate. If there is an afterburner failure, or if there is a momentary power failure, then water sprays are also activated to cool the oven down. This will prevent smoke emissions from the stack. For better temperature control, the APC fires the burners high and low instead of On and Off. The frequency of lighting failures and wear on the burners will be reduced. The APC will not allow the oven to turn off while any combustible materials remain in the oven. The APC will turn the oven off automatically when the load is complete. The APC is a significant improvement over cycle time control or ramp & soak control.

- APC will prevent fires, part damage & operator injury.

- APC provides faster and safer processing than other control systems.

- APC is not a “Ramp & Soak” control. “Ramp & Soak” control requires that exact cycle profiles be programmed in the controller and that the operator be able to select the appropriate program for the load to be processed. APC will automatically adjust to the load and requires no program selection.

Unique Top/Down Heating Design

Top/Down Heading is a unique patented exterior multi-chamber design in which the oven is heated from the top to the bottom. The primary (oven) burner releases heat in the top of the oven and the afterburner removes cool air and combustible products from the bottom. The positioning of the burners is the reverse of other burn-off ovens.

- Parts and carts aren’t blasted with hot gases; thus, they are less likely to be damaged.

- Combustible smoke naturally sinks to the floor in a burn-off oven where it is continuously removed; thus, fires are prevented and efficiency is improved.

- 100% of heat passes through parts before being removed; thus, efficiency & cycle times are better.

- Exterior chambers eliminate damage during loading and unloading; thus, maintenance is reduced.

NFPA/FM/UL Standards

The Steelman burn-off oven is built to the standards of the National Fire Protection Association (NFPA) where applicable and Factory Mutual Insurance (FM). Other standards by Industrial Risk Insurers (IRI), Canadian Gas Association (CGA), etc., can be substitued at small charge (contact factory). Consult the factory for the respective standard. The NFPA & FM standards include such features as a high/low gas pressure switch, purge timer, door switch, main safety shutoff valves for ovens over 400,000 BTU/Hr, and others. Our control panels are UL listed.

Industrial Quality Burners

Also, unlike other burn-off oven manufacturers, Steelman uses industrial quality burners. These burners are built to significantly greater durability and reliability standards than the light duty sheet metal burners used by other manufacturers. Also, these industrial quality heavy duty burners are available with inputs exceeding 1 million BTU/Hr.

- Increased BTU/Hr inputs contribute to decreased cycle times.

- Improved durability & reliability means less down time, less service and lower maintenance cost.

- Industrial Quality Burners provide lower Nox and CO emissions.

High Fire Afterburner

A high fire afterburner is included standard with every oven, allowing the afterburner to rapidly heat up and maintain a minimum of 1,500°F during operation. This assures that the afterburner will always be ready to process vapors produced in the oven. Other systems that don’t incorporate a high fire burner may emit smoke and odor while the afterburner is heating up. This benefit also allows the oven to process at a maximum rate. In addition, the residence time in the afterburner is 1/2 second or more. This is important to achieve total destruction of smoke and fumes. Many competitors have a much shorter residence time.

- This feature is environmentally preferred and already required in some states.

- The high fire afterburner will reduce cycle times.

Construction Second to None

All Steelman burn-off ovens undergo the same meticulous fabrication. The construction starts with an angle iron frame and a 14 gauge CRS exterior. The floor is built out of 4″ channel and insulated with 1/2″ ceramic fiber and 3 1/2″ of refractory cement. The oven includes a five layer protection system in the walls & ceiling: two layers protect against corrosion, two layers insulate, and the aluminized perforated steel covers the entire interior eliminateing mechanical damage. A pressure relief hatch is located on the top of the oven to prevent operators from being harmed in the event of an ignition. The afterburner chamber and exhaust stack are constructed of stainless steel and lined with a 1/2″ ceramic sleeve and a 1 1/2″ ceramic blanket. Finally, Steelman burn-off ovens include an exclusive ergonomically designed track system. A short section of track is allowed to fold on its side in order that the oven doors can be opened and closed over the track.

Exhaust Installation Kit Included

Exhaust kits include 14 linear feet of exhaust stack over the top of the oven. Also included are rain cap and flashing. Stack lengths are constructed of stainless steel and lined with ceramic fiber. Additional stack lengths, elbows, dampers and other accessories are available from the factory.

Steelman Burn-Off Oven Construction Process

This is a Steelman Model # 101224BBR during all stages of production. It is unique for its size, 10′ wide x 12′ tall x 24′ deep, but it is a good example of standard Steelman Burn-off oven construction. This oven is now being used to remove rubber from rollers.

1. The frame is complete and the 3.5″ refractory floor has been poured

over 1/2″ceramic fiber. The “grid” that can be seen in the floor is 4″ channel.

2. Fourteen-gauge cold rolled steel is being used to make the outer wall.

3. The outer skin is complete. The three layers of interior wall

can be seen going up: pookie, tar paper (both for

corrosion protection), and 3.5″ mineral wool insulation.

4. The walls are complete. A 1″ ceramic fiber layer has been added

and then protected by aluminized perforated steel.

5. The doors have been hung, and the muscles of the operation,

the heating burners have been added to the left side.

The high-fire afterburner has been installed. The stainless steel

and ceramic fiber exhaust stack can be seen covered in white paper.

6. The UL Listed control panel has been added and the painter

has had his turn with it as well. It is first covered with a zinc rich primer

and then finished with Steelman Tough Gray enamel.

Now off to the testing area!

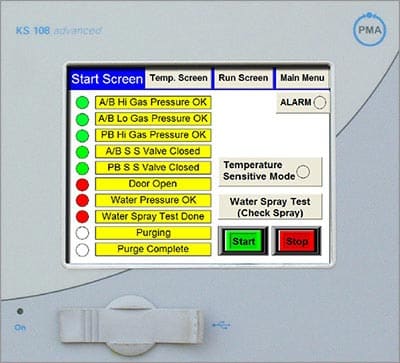

Burn-Off Oven Programmable Logic Control

Steelman is the leader in oven control technology by offering the PLC or Programmable Logic Control. This PLC control system includes a single touch-screen interface that replaces the three separate Honeywell controllers and offers many advantages, including:

- Network Monitoring: Connect the oven to your local network to monitor your process and access any of the multiple screens.

- System Alarms: Alerts the operator of any problems and makes troubleshooting much easier.

- Datalogger: Records temperatures, times, and events to a file for later viewing.

- Temperature Trending: Displays a real-time graph of the temperatures of your process.

- Custom Screens Available: Set up a custom screen to display the information that is important to you.

- Online Training: Log on remotely with our engineers and receive training on your oven before it ships.

Our programmable oven control system is available for new industrial ovens.

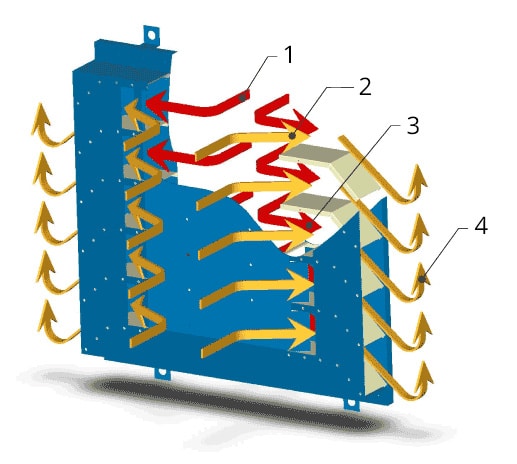

Steelman Heat-Cleaning Oven with Exclusive Venturi Diffuser

Steelman Heat-cleaning Ovens now use a patented venturi diffuser to distribute heat in the oven. This design circulates oven air through the diffuser where it mixes with burner gases to dramatically reduce the temperature of hot gas entering the oven. This means that your valuable parts will not be overheated in a Steelman oven. Also, smoke produced in the oven burns in the diffuser to produce free heat for higher efficiency.

Steelman Venturi Diffuser Breakdown

- Hot burner gases enter diffuser.

- Venturi slot creates low-pressure and pulls in oven gas.

- Burner and oven gases mix.

- Cooled gases leave diffuser and circulate to the top of the oven.

Steelman’s patented (5,857,455) Venturi Diffuser cools hot burner gases before they can damage your parts by mixing them with cooler oven gases before they enter the oven. In addition, smoke from the parts is burned in the diffuser to contribute free fuel to the process.